X-ray optical systems represent cutting-edge technology borrowed from astrophysics and medical imaging that’s revolutionizing how camera manufacturers design modern lenses. While you won’t find actual X-ray components in your DSLR or mirrorless camera, the precision manufacturing techniques and optical design principles developed for X-ray telescopes and synchrotron facilities have directly influenced the ultra-high-resolution glass elements in today’s premium photography equipment.

Consider how Zeiss and Canon’s recent flagship lenses achieve unprecedented sharpness across the entire frame—this stems from computational modeling methods first perfected in X-ray optics laboratories. These advanced design approaches allow engineers to correct microscopic imperfections that would otherwise cause chromatic aberration, field curvature, and other image-degrading issues that plague lesser lenses.

The connection runs deeper than manufacturing precision. X-ray optical research has pioneered novel lens coatings, aspherical element designs, and multi-layer optical stacks that minimize light scatter and maximize transmission—the same innovations that make your f/1.4 prime lens capable of tack-sharp images wide open, even in challenging backlit conditions.

Understanding this technological crossover helps you make smarter gear investments. When lens manufacturers tout “advanced optical formulas” or “nano-crystal coatings,” they’re often referencing design philosophies refined through decades of X-ray optics research. This article demystifies these connections and shows you exactly which specifications indicate genuine optical excellence versus marketing hyperbole, empowering you to choose lenses that deliver measurable real-world performance improvements.

What X-Ray Optical Systems Actually Are (And Why Photographers Should Care)

The Physics Behind the Magic

X-rays present a unique challenge because they don’t behave like visible light—they pass straight through most materials instead of reflecting or refracting predictably. This means conventional lens designs simply won’t work. Scientists and engineers have developed three clever workarounds that have fascinating parallels to advanced optical technologies in modern camera systems.

**Grazing incidence mirrors** work by catching X-rays at extremely shallow angles—imagine skipping a stone across water rather than throwing it straight down. When X-rays hit a specially polished surface at less than one degree, they bounce off instead of penetrating. Telescopes like NASA’s Chandra use nested cylindrical mirrors to focus X-rays from distant cosmic sources.

**Fresnel zone plates** function like lightweight, flat lenses made of alternating transparent and opaque rings. These circular patterns create constructive interference, focusing X-rays to a point—similar to how a pinhole camera creates an image, but far more efficient. Think of them as precision diffraction gratings specifically tuned to extreme wavelengths.

**Multilayer coatings** stack hundreds of ultra-thin layers—each just atoms thick—to create artificial “mirrors” that reflect X-rays at specific wavelengths. By carefully controlling layer thickness and materials, engineers can tune these coatings to enhance reflection at chosen energies, much like anti-reflective coatings optimize visible light transmission in your camera lenses, though working at opposite ends of the electromagnetic spectrum.

From Space Telescopes to Your Camera Bag

The journey from capturing distant X-rays in space to sharpening your landscape photos is more direct than you might think. When NASA launched the Chandra X-ray Observatory in 1999, engineers developed revolutionary coating technologies to focus X-rays—normally impossible to bend with conventional glass. These specialized multilayer coatings, designed to manipulate electromagnetic radiation at extreme wavelengths, caught the attention of optical engineers in the photography industry.

The real breakthrough came when researchers realized these same principles could reduce lens aberrations and improve light transmission in camera optics. Companies like Zeiss and Canon adapted similar coating methodologies, creating advanced anti-reflective treatments that minimize ghosting and flare while maximizing contrast. The precision required for space telescope mirrors—measured in nanometers—translated directly into manufacturing techniques for aspherical lens elements.

Today’s high-end camera lenses benefit from this space-age heritage. Those multi-coated elements in your telephoto lens? They’re distant cousins of Chandra’s mirror technology. The ultra-precise grinding and polishing techniques, originally developed to shape telescope optics, now ensure your lenses deliver edge-to-edge sharpness. It’s a perfect example of how pushing the boundaries of space exploration ultimately lands tangible improvements in your camera bag.

Breakthrough Lens Technologies Borrowed from X-Ray Systems

Multilayer Coatings That Revolutionized Image Quality

The quest to eliminate reflections in X-ray mirrors led researchers to develop incredibly precise multilayer coating techniques—stacking alternating materials at nanometer-scale thicknesses to control how light behaves. Camera manufacturers recognized that these same principles could revolutionize optical lens design, particularly in combating internal reflections that cause flare and reduce contrast.

Traditional anti-reflective coatings on camera lenses typically use three to seven layers. Thanks to X-ray optics research, modern high-end lenses now employ nine, eleven, or even more coating layers with unprecedented precision. Canon’s Subwavelength Structure Coating (SWC) and Nikon’s Nano Crystal Coat both draw from principles first perfected in X-ray mirror technology, arranging microscopic structures smaller than visible light wavelengths to minimize reflections.

The improvements are measurable and dramatic. Lenses using advanced multilayer coatings show reflection rates below 0.5% across the visible spectrum, compared to 1.5-2% for conventional coatings. While that sounds modest, it translates to noticeably improved performance when shooting into bright light sources. Professional photographers regularly working in challenging lighting—think wedding photographers capturing backlit ceremonies or landscape shooters facing sunrise—report significantly reduced ghosting and veiling flare.

Consider Sony’s G Master lenses, which use Nano AR Coating II technology. Side-by-side comparisons with earlier models show approximately 60% reduction in flare intensity and measurably higher contrast ratios, particularly in high-dynamic-range scenes. The Zeiss T* coating, enhanced with modern multilayer techniques, has become legendary for its clean rendering even in harsh backlighting conditions.

These coatings don’t just improve technical metrics—they preserve the micro-contrast and color saturation that give images their three-dimensional “pop.” For photographers, that means cleaner files requiring less post-processing correction and greater creative freedom when composing against challenging light sources.

Precision Manufacturing and Aspherical Elements

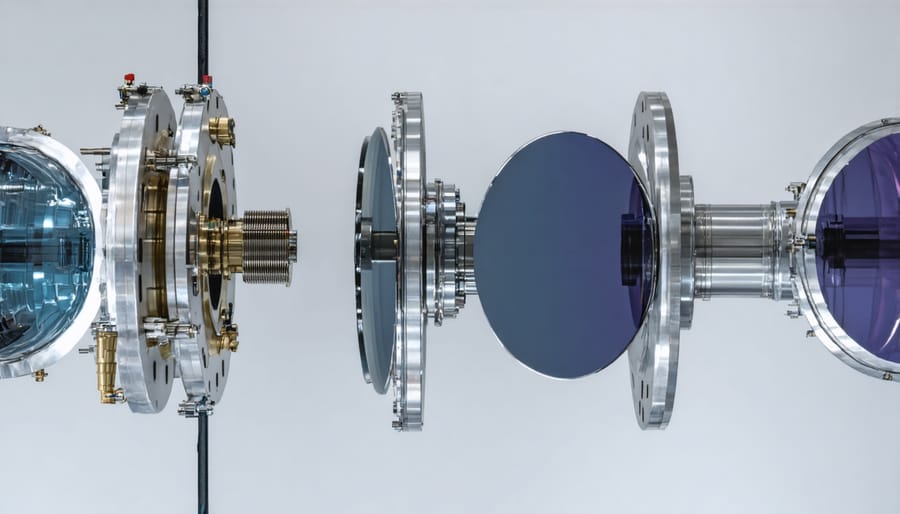

The world of X-ray optics demanded something extraordinary from manufacturers: precision measured in nanometers. When scientists needed to focus and direct X-rays for applications like medical imaging and materials research, they couldn’t rely on traditional lens-making techniques. X-rays pass through most materials, so these optical systems required specialized mirrors and surfaces polished to unprecedented accuracy—we’re talking surface irregularities smaller than a single wavelength of light.

This extreme precision didn’t stay confined to research laboratories. The manufacturing technologies developed for X-ray systems—particularly computer-controlled polishing and advanced metrology equipment—eventually trickled down to camera lens production. Suddenly, creating complex aspherical lens elements became economically viable. Unlike traditional spherical lenses that follow a simple curved surface, aspherical elements feature variable curvature across their surface, allowing them to correct multiple optical aberrations with a single piece of glass.

The impact on your images is tangible. Modern lenses incorporating precision-manufactured aspherical elements deliver sharper corner-to-corner performance, reduced distortion, and better control of spherical aberration—that softness you sometimes see when shooting wide open. These groundbreaking innovations allow lens designers to achieve optical quality that was theoretically possible but practically impossible just decades ago.

Consider your 24-70mm f/2.8 zoom lens. That compact workhorse likely contains several aspherical elements that keep images crisp across its zoom range while maintaining a reasonable size and weight. Without the manufacturing precision pioneered for X-ray applications, you’d need significantly larger, heavier lenses—or accept compromised image quality. The connection between medical imaging technology and your weekend landscape shoot might seem distant, but it’s remarkably direct.

How These Innovations Show Up in Your Photography

Better Low-Light Performance and Contrast

One of the most dramatic improvements from advanced optical coatings and precision manufacturing is how modern lenses handle challenging lighting situations. If you’ve ever shot a concert, captured city lights at dusk, or photographed a subject with the sun behind them, you know the frustration of muddy shadows and washed-out highlights. This is where X-ray-inspired optical technologies really shine—literally.

The multi-layer anti-reflective coatings developed through high-precision techniques similar to X-ray optics fabrication dramatically reduce veiling glare, that hazy fog that appears when strong light sources enter your lens. In practical terms, this means when you’re shooting a musician on stage with bright backlighting, their silhouette remains crisp and defined rather than swimming in a milky haze. The shadows retain detail and texture instead of collapsing into featureless black voids.

Dynamic range—the gap between the darkest darks and brightest brights your camera can capture—also benefits enormously. Better coatings mean less light scatter within the lens barrel, preserving more tonal information at both extremes. That translates to wedding photographers capturing both the bride’s white dress and the groom’s black tuxedo with full detail, even in mixed lighting conditions.

For night photography enthusiasts, these improvements are game-changing. Street lights and neon signs no longer bloom into distracting starbursts, while the surrounding shadows maintain enough detail to convey atmosphere and context. Your images gain a cleaner, more three-dimensional quality that separates professional-grade results from snapshots.

Sharper Images Across the Entire Frame

One of the most frustrating aspects of traditional lens design has been edge performance—that annoying softness that creeps into the corners of your frame, especially when shooting wide open. Advanced manufacturing techniques borrowed from x-ray optical systems are changing this equation dramatically.

Modern aspherical lens elements, precision-ground with tolerances measured in nanometers, maintain sharpness from the center of your image all the way to the corners. Think about shooting architectural interiors: those vertical lines at the edges of your frame stay crisp and well-defined, even at f/2.8. No more stopping down to f/8 just to get acceptable corner sharpness, which means you can maintain faster shutter speeds in challenging light.

Chromatic aberration—those purple or green color fringes that appear along high-contrast edges—has similarly benefited from these precision manufacturing advances. Extra-low dispersion glass elements, positioned with micrometer-level accuracy, work together to keep different wavelengths of light focused on the same plane. When photographing a backlit building against a bright sky, you’ll notice clean edges without the telltale color fringing that plagued earlier lens designs.

Landscape photographers see perhaps the most dramatic benefits. Imagine capturing a sunrise with detailed tree branches silhouetted against the sky—branches that remain sharp and fringe-free even in the extreme corners of your composition. Or consider a panoramic cityscape where buildings maintain their structural integrity across the entire frame, allowing you to crop and print aggressively without worrying about soft edges.

These improvements aren’t just theoretical spec-sheet bragging rights. They translate directly into images that hold up under scrutiny, whether you’re printing large or cropping significantly in post-production. The edge-to-edge consistency means more of your creative composition actually works, rather than fighting against optical limitations.

Which Camera Lenses Actually Use This Technology

Premium Lens Lines Leading the Way

The world’s leading lens manufacturers have invested heavily in optical technologies that trace their roots directly back to X-ray and space-based research, bringing cutting-edge science into the hands of everyday photographers.

**Canon’s L-series** lenses showcase this technological evolution beautifully. Their proprietary Subwavelength Structure Coating (SWC) and Air Sphere Coating (ASC) technologies use nano-scale structures smaller than the wavelength of visible light—principles borrowed from precision optics used in scientific imaging. SWC reduces flare and ghosting by essentially creating an optical surface so fine-tuned that light can’t “find” a boundary to reflect off. Think of it as the optical equivalent of stealth technology. These coatings make a noticeable difference when shooting directly into the sun or working with strong backlighting.

**Nikon’s Z-mount** system employs their ARNEO and Nano Crystal Coats, which similarly manipulate light at microscopic levels. ARNEO coating specifically targets vertical incident light—the kind that causes those frustrating rainbow-like flares in architectural photography. It’s this kind of game-changing photo technology that separates professional glass from consumer alternatives.

**Sony’s G Master** lineup features their original Nano AR Coating II, which achieves near-complete elimination of internal reflections. Professional wedding and event photographers particularly appreciate how these coatings handle mixed lighting conditions where cheap lenses would produce muddy, low-contrast images.

Even third-party manufacturers like Sigma and Tamron have joined the advanced-coating race, with Sigma’s Super Multi-Layer Coating and Tamron’s eBAND (Extended Bandwidth & Angular-Dependency) coating bringing professional-grade optical performance to more accessible price points. The practical result? Sharper images with better contrast, especially in challenging lighting situations.

Affordable Options That Benefit Too

The good news? You don’t need a $2,000 lens to benefit from X-ray optical system innovations. Trickle-down technology has made these advances accessible across various price points.

Consider the Canon RF 50mm f/1.8 STM, retailing around $200. This budget-friendly lens incorporates computer-designed aspherical elements—technology refined through the same simulation methods used in X-ray optics. The result? Sharp images with minimal chromatic aberration, rivaling older, more expensive designs.

Tamron’s affordable 28-75mm f/2.8 G2 (roughly $900) showcases how third-party manufacturers leverage advanced optical modeling. Its coating technology reduces ghosting and flare significantly better than similarly-priced lenses from just five years ago. Photographers shooting backlit subjects notice the difference immediately.

Even entry-level kit lenses benefit. The Nikon Z 24-50mm f/4-6.3, often bundled with cameras, uses precision molding techniques developed from high-end optical research. While not matching professional glass, it delivers respectable sharpness that would’ve required mid-range pricing a decade ago.

The democratization of these technologies means hobbyists and budget-conscious professionals can achieve results once reserved for those with premium gear. Smart optical design now matters more than simply throwing expensive glass elements at a problem.

What’s Coming Next: The Future of Cross-Industry Optical Innovation

The optical innovations happening right now are nothing short of extraordinary, and they’re happening faster than ever before. Scientists and engineers are borrowing techniques from X-ray optics labs and applying them to everyday camera gear in ways that would have seemed like science fiction just a decade ago.

One of the most exciting developments is computational photography combined with advanced optical coatings. Think of it as your camera’s lens and processor working together like never before. Multi-layer nano-coatings, inspired by X-ray mirror technology, are being designed to manipulate light at wavelengths we never thought possible in consumer cameras. These coatings can potentially reduce chromatic aberration to near-zero levels while maximizing light transmission across the entire visible spectrum. For photographers, this means sharper images with more accurate colors straight out of camera.

Material science is another frontier that’s genuinely thrilling. Researchers are experimenting with metamaterials—artificially engineered materials with properties not found in nature—that could revolutionize lens design. These materials might allow manufacturers to create lighter, thinner lenses that perform better than traditional glass elements. Imagine a telephoto lens with the image quality of today’s best prime lenses but weighing half as much.

The integration of these technologies represents revolutionary camera technology that’s already beginning to trickle down from research labs to production floors. Companies are testing adaptive optics systems—technology borrowed directly from astronomy and X-ray imaging—that could allow lenses to automatically correct for atmospheric distortion or internal aberrations in real-time.

What does this mean for you as a photographer? Within the next five to ten years, expect cameras that can see better in low light, lenses that weigh less but perform better, and image quality that pushes beyond what we currently consider possible. The cross-pollination between specialized optical systems and consumer photography equipment isn’t slowing down—it’s accelerating.

Should This Technology Influence Your Next Lens Purchase?

The honest answer? Unless you’re shooting specific genres at the highest professional level, lenses explicitly marketed around X-ray-inspired optical technology probably aren’t essential for your next purchase. But understanding the principles behind them can absolutely inform smarter buying decisions.

Here’s a practical framework: If you regularly shoot high-contrast scenes—think wedding ceremonies with dramatic lighting, architectural photography with strong directional light, or astrophotography where controlling flare is critical—lenses incorporating advanced coating technologies derived from X-ray optics research deliver measurable improvements. You’ll see this in reduced ghosting, better color accuracy in challenging conditions, and improved contrast that requires less post-processing correction.

For landscape and studio photographers working in controlled lighting, these benefits matter less. Your investment dollars might better serve you elsewhere, perhaps in accessories that elevate your photography through improved workflow rather than marginal optical gains.

Budget consideration is straightforward: premium lenses with cutting-edge optical designs typically cost 30-50% more than their predecessors. Ask yourself whether that investment translates to tangible improvements in your finished images. A $2,000 lens with advanced coatings won’t magically improve composition or storytelling, but it might eliminate frustrating technical limitations holding back otherwise strong work.

The sweet spot? Mid-range lenses from major manufacturers increasingly incorporate trickle-down technology from flagship designs. You’re getting many of the same coating benefits without the premium price tag. Research specific lens reviews focusing on real-world flare resistance and color rendition rather than marketing terminology about “advanced optical systems.”

Bottom line: Buy for your actual shooting needs, not theoretical technical specifications. If you can’t identify a specific problem in your current work that better optics would solve, invest in skill development first, glass second.

It’s remarkable how scientific disciplines that seem worlds apart from photography—like X-ray astronomy and synchrotron research—have quietly revolutionized the lenses we use every day. The sophisticated coating technologies, precision grinding techniques, and optical simulation software that enable scientists to bend X-rays into focus have trickled down into the camera gear sitting in your bag right now. Those ultra-sharp corners and minimal flare you enjoy? Thank the engineers who borrowed from particle physics labs.

This cross-pollination between unexpected fields reminds us that photography sits at the intersection of art and cutting-edge science. While it’s fascinating to understand the engineering heritage behind your equipment, what ultimately matters is the images you create with it. The best lens is the one that helps you capture your vision, regardless of whether its coatings were inspired by space telescopes or its aspherical elements by synchrotron mirrors.

When shopping for modern lenses, look beyond marketing buzzwords. Pay attention to practical indicators of advanced optical design: multi-layer nano coatings that reduce ghosting in backlit situations, aspherical elements that maintain sharpness edge-to-edge, and fluorite or ED glass that minimizes chromatic aberration. Read real-world reviews, test lenses in conditions you actually shoot, and remember that technical perfection means nothing if the lens doesn’t suit your creative workflow. Understanding the science makes you informed; using that knowledge to create compelling photographs makes you an artist.